Reassessment of an Anchored Diaphragm Wall in Stiff London Clay

- Aug 4, 2025

- 4 min read

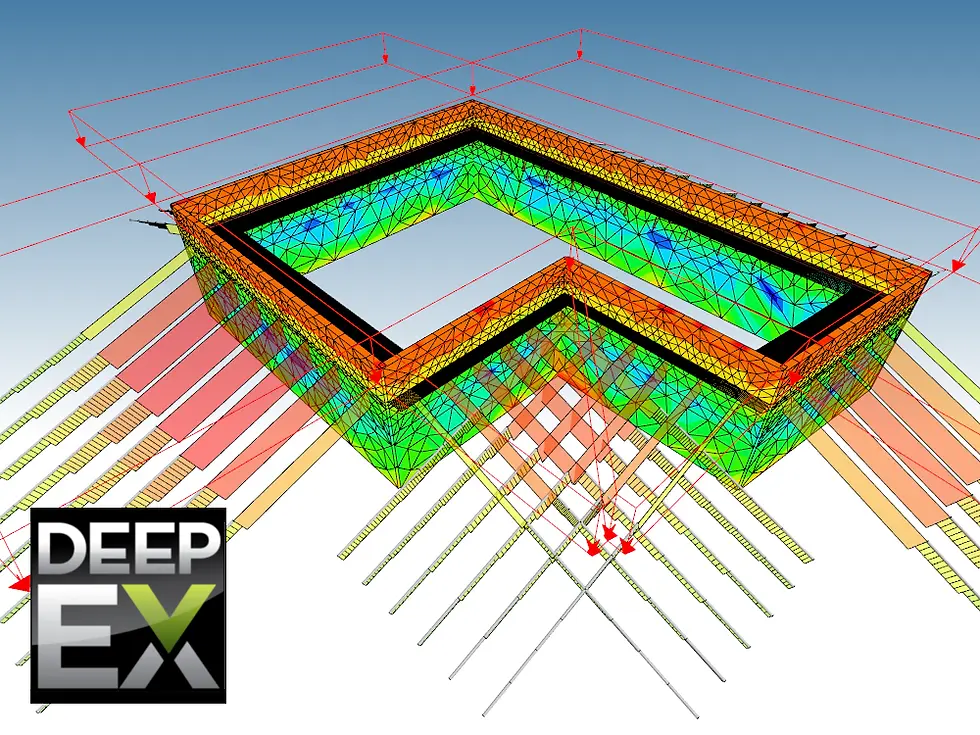

LEM and FEM in DeepEX

Introduction

In this study, we revisit the excavation documented by Sills et al. (1978) in their seminal work “Behaviour of an Anchored Diaphragm Wall in Stiff Clay.” The original case focused on a diaphragm wall embedded in stiff London clay, supported by four rows of anchors, and extensively instrumented to monitor surface and internal displacements during and after excavation of an 8 m deep cutting.

The instrumentation included monitoring pore pressures, anchor loads, and displacements, and the original findings highlighted notable block movements and strain zones beyond the influence of the anchors, as presented in Figure 1.

Figure 1. Soil stratigraphy, and original geometry and layout from Sills et al. (1978).

Modelling Approach

To reassess this case history, we used DeepEX software for an integrated framework combining Limit Equilibrium Method (LEM) and Finite Element Method (FEM). The original geometric and support system configurations were maintained, along with the published shear strength parameters of the London clay (Figure 1).

However, assumptions had to be made regarding:

- Soil deformability characteristics (Young’s modulus).

- Tieback anchor configurations, and ultimate bond resistance for the anchors.

Figure 2. Geometry modelled in DeepEX with soil and support system layout.

Preliminary Stability Assessment – LEM

The preliminary stability assessment was carried out using the Limit Equilibrium Method (LEM), which remains a standard approach for evaluating the global stability of retaining systems during staged excavations. LEM analyses rely on predefined failure surfaces and use idealised pressure distributions to represent soil loads acting on the wall. In this context, well-established apparent earth pressure diagrams—such as those proposed by Peck (1969) for braced excavations—were employed to define the pressure envelope applied to the wall.

These diagrams offer a simplified yet practical means of estimating soil pressures at different excavation stages, considering wall stiffness and excavation depth. The LEM analysis provided an initial assessment of overall stability and enabled the determination of preliminary prestress values for the anchors, ensuring sufficient resisting capacity against the mobilised earth pressures in each stage. This approach offers a reliable basis for early design while serving as a benchmark for comparison with more advanced numerical analyses.

The initial analysis was conducted using LEM to evaluate global stability of the wall during excavation stages and determine the preliminary prestress values for the anchors.

The LEM results showed that with appropriate prestress levels, the system-maintained stability throughout the excavation stages.

Figure 3. LEM Results: Bending Moment distribution during excavation.

Figure 4. LEM Results: Shear force and earth pressure distributions.

Final Stability and Deformation Assessment – FEM

The detailed stability assessment was further developed using the Finite Element Method (FEM), which offers a more comprehensive analysis by simulating the actual stress–strain behaviour of soil and the interaction between soil and structural elements. Unlike LEM, FEM does not rely on assumed failure surfaces or empirical pressure diagrams; instead, it calculates the distribution of stresses, deformations, and internal forces based on the material properties and staged construction sequence. In this analysis, the excavation process and support installation were modelled incrementally, allowing for a realistic simulation of stress redistribution and progressive failure. The soil–structure interaction was explicitly captured, enabling the evaluation of wall deformations, ground surface settlements, and the mobilised forces in anchors or struts. This approach not only provides insight into the serviceability performance of the retaining system but also supports the optimisation of support configurations and construction sequences based on predicted displacements and safety margins.

FEM analysis was then performed using three-nodded triangular elements, with increased mesh refinement near the wall to better capture stress and deformation gradients.

The FEM results provided:

- Detailed bending moment profiles

- Accurate horizontal displacements

- Superficial settlement predictions

These outputs closely matched the field measurements reported in the original study, particularly the horizontal displacements up to 50 mm and the observed block movement of the wall and surrounding soil.

Figure 5. FEM Results: Bending moment and horizontal displacement along the wall.

Figure 6. FEM Results: Shear stress and total earth pressures.

Conclusion

This reassessment demonstrates the capability of integrated LEM+FEM modelling in DeepEX to replicate real-world excavation behaviour, even with limited input on soil deformability and tieback characteristics. Key conclusions include:

- Assumed deformability values typical of London clay produced displacement results closely matching field data.

- LEM proved valuable for initial stability and prestress design.

- FEM effectively captured wall deformation, block movement, and stress redistribution during excavation.

- The use of DeepEX allowed efficient transition between LEM and FEM frameworks while maintaining modelling consistency and obtaining satisfactory results.

This study reinforces the value of modern tools in revisiting historical case studies and provides a reliable method for analysing similar future projects.

Bibliography

Sills, G. C., Vaughan, P. R., & Ward, W. H. (1978). Behaviour of an anchored diaphragm wall in stiff clay. Géotechnique, 28(4), 423–445. https://doi.org/10.1680/geot.1978.28.4.423

Peck, R. B. (1969). Deep excavations and tunneling in soft ground. Proceedings of the 7th International Conference on Soil Mechanics and Foundation Engineering, Mexico City, State-of-the-Art Volume, 225–290.

Deep Excavation LLC. (n.d.). DeepEX – Deep excavation design software. Retrieved from https://www.deepexcavation.com/

Let us show you how to reduce your design time by up to 90%!