🌍Geoengineering Master Class #2

- Dec 16, 2025

- 4 min read

How to Determine Realistic Prestress Loads for Ground Anchors in DeepEX

Ground anchors play a crucial role in the performance of deep excavations. Before the wall ever reaches its final depth, anchors begin resisting active soil pressures stage by stage, helping control wall movements and ensuring structural safety. But a common challenge engineers face is determining what prestress load should be applied to each anchor level so that the system responds realistically once construction begins.

In this second episode of the Geoengineering Master Class, you will learn a practical and dependable workflow for predicting these prestress loads using traditional Limit Equilibrium (LEM) analysis, and then applying those values to Nonlinear (NL) and Finite Element Method (FEM) simulations inside DeepEX. This approach is widely accepted in practice, and with DeepEX, the entire process becomes much faster and much more intuitive.

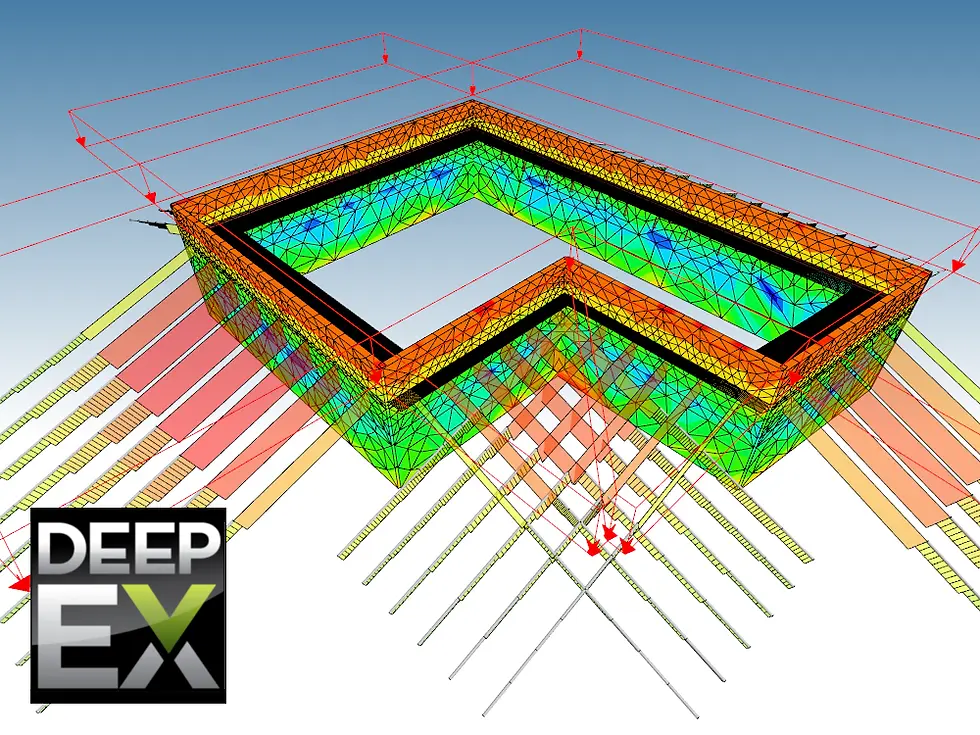

Figure 1: Deep excavation with tiebacks – DeepEX LEM analysis

What You Will See in the Video

The accompanying video lesson demonstrates the full process in real time:

Building and running the frictionless LEM model

Optimizing the ground anchors fixed length and structural sections

Identifying anchor reactions across stages

Selecting prestress values and updating anchor properties

Copying the model and running NL and FEM versions

Introducing wall friction and reviewing the results

Comparing wall movements, bending moments, and system stability

By the end of the episode, you will be able to adopt the same workflow for your own excavation projects and establish prestress values that are practical, defensible, and aligned with engineering best practices.

Watch the video here:

Starting with LEM: Why It’s Still the Most Reliable First Step

Even though more advanced tools like NL and FEM offer remarkable insights into soil–structure interaction, most engineers still begin with a simple LEM model. This isn’t a limitation — it’s a strength. LEM provides quick, conservative, and easy-to-understand results that form the foundation of a well-calibrated design.

To make LEM even more informative for prestress determination, it is recommended to run the first version without any wall friction. When you eliminate wall–soil interface friction, the excavation system becomes more dependent on its bracing. This means the anchors take on slightly higher loads, allowing you to establish a conservative baseline for prestress selection.

Inside DeepEX, this step is straightforward. You simply disable wall friction in the analysis settings, run the staged LEM simulation, and then begin reviewing the support reactions for each anchor level through all construction stages.

Finding the Critical Load for Each Anchor Level

One of the advantages of working in DeepEX is that the program automatically calculates and organizes support reactions at each construction stage. This makes it easy to navigate through the timeline of your excavation and identify where each anchor reaches its maximum demand.

A key point to remember is that the last construction stage is not necessarily the most critical one. Depending on the geometry, soil properties, and drainage conditions, an anchor might see its peak demand well before the excavation reaches its final depth.

By reviewing the reactions produced in the frictionless LEM model, you can determine the maximum reaction for each anchor level. These values serve as your reference point for selecting a realistic prestress.

Assigning Prestress Loads the Practical Way

In common practice, engineers typically apply about 80% of the critical LEM reaction as the prestress load. This provides a balanced value that is sufficiently high to control deformations, yet still reasonable given real-world construction tolerances, system variability, and partial lock-off losses.

DeepEX allows you to return directly to the anchor installation stage and enter this prestress value for each anchor. You repeat this process for all bracing levels, ensuring that the entire support system is calibrated before moving on to more advanced analysis methods.

Transitioning to NL and FEM: Creating Detailed, Realistic Behavior Models

Once the prestress values are assigned, the next step is to evaluate the system under more realistic ground–structure interaction models. DeepEX makes this incredibly simple, as you can create exact copies of your calibrated LEM model and switch each copy to a different analysis method.

A common approach is to create:

A Nonlinear (NL) version using Winkler springs,

And a 2D Finite Element Method (FEM) version for continuum-based behavior.

These advanced models should include reasonable wall friction, since NL and FEM methods are designed to capture interface effects, soil stiffness, staged stress accumulation, and load redistribution.

By introducing wall friction and running the analyses again, you obtain a much clearer picture of how the excavation system will actually behave in the field — including bending moments, wall deflections, and shear forces that evolve based on previous stages.

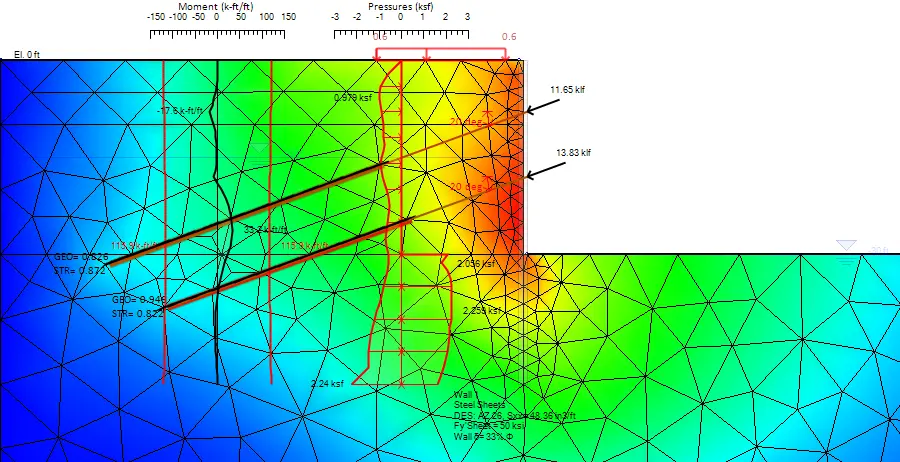

Figure 2: Deep excavation with tiebacks – DeepEX FEM analysis

Why the Combined Approach Works So Well

The real strength of this workflow lies in comparing a simple analytical model with more advanced numerical simulations. Your LEM model provides conservative support reactions and a stable baseline for prestress. NL and FEM then refine the picture by simulating accumulated stresses, nonlinear soil responses, and structural stiffness.

Because DeepEX allows you to switch between all three methods within the same project file, you can compare results rapidly and confidently. You are able to see how moments and displacements evolve from stage to stage, verify that prestress levels are appropriate, and confirm that the system behaves safely under multiple independent analytical viewpoints.

This integrated environment makes DeepEX uniquely valuable, especially for projects where design decisions must be defended, optimized, and validated using diverse analytical approaches.

Coming Next: Helical Pile Optimization in DeepFND

In the next Master Class, we shift to deep foundations. You’ll learn how to optimize helical pile sizes and helix configurations using DeepFND. We will apply vertical loads, test multiple pile layouts in a single file, check the individual plate and the cylinder method capacities for each examined case, and compare capacities to find the most efficient solution.

Stay tuned — and prepare to take your geotechnical modeling to the next level.

Let us show you how to reduce your design time by up to 90%!