Reducing uncertainties in pile capacities with TXDOT methods

- Apr 1, 2024

- 4 min read

You must read this if you are using the traditional TxDOT TCP methods for drilled piles!

An honest introduction:

We are a private company and we just spent over $4000 to give you what we think is an invaluable insight into drilled pile capacities in Texas. We obviously plan to sell you something at the end of this article otherwise we would not exist as a private entity. That something is our deep foundation software DeepFND which incorporates all the methods that we are presenting below. Even if you don’t buy it, we hope that you take away from this the need to not use only existing TxDOT TCP methods in your next drilled pile project.

Dimitrios Konstantakos, P.E.

CEO Deep Excavation LLC

What you need to read:

Minimize risks for TxDOT TCP drilled pile capacity methods

When it comes to drilled pile foundations predicting the axial capacity is crucial. In Texas where geology does not allow regular standard penetration testing (SPT), it is very common to use the available TxDOT methods based on the Texas cone penetrometer results (TCP). These charts were developed in 1956 and provide one chart for all rock types for both allowable skin friction and end bearing (Figure 1). These allowable values incorporate a safety factor of 3.

Figure 1: 1956 TxDOT Charts

Recognizing that actual Texas rock formations vary significantly Salman et. all in 2021, and 2024 proposed two alternative methods for estimating drilled pile capacity using TCP. In the 2021 method (Figure 2), charts for allowable skin friction and end bearing were presented for different formations. In the 2021 charts, end bearing was provided for sandstones and hard shales. What is evident from these charts is that the current TxDOT methods are more representative of limestone. For hard and weathered shales end bearing and shaft resistance are significantly smaller vs. the TxDOT manual values.

Figure 3 compares the original TxDOT methods vs. the 2021 proposals for a 30-inch drilled pile with a 15 ft socket in bedrock. For the current TxDOT method all geology formations produces allowable and Ultimate capacities of 458.18 and 1,222.64 tons. Using the new proposed design charts from this research the Hard Shale formation allowable capacity of 228.79 tons is approximately 50% of the TxDOT predicted. For a Limestone formation the allowable capacity of 481.74 tons is 5.1% greater vs. the TxDOT value. In a Sandstone formation the allowable capacity of 3,896.80 tons is 750% of the TxDOT values.

Figure 2: Proposed 2021 charts vs. current TxDOT

Figure 3: Comparison predicted pile capacities 2021 charts vs. TxDOT manual

In 2024, Salman et. al. proposed a set of equations for predicting pile capacity from TCP based on statistical analyses and regressions for the field and laboratory parameters. Numerical and regression modelling of the rock properties and strength were considered to develop numerous equations for rock properties, strength, and drilled shaft bearing capacities, as well as equations for predicting TCP, Qun, skin friction, and end bearing for various geologic formations. These equations require more input vs. the 2021 charts, such as the moisture content, the dry density, core recovery, RQD, but provide a more rational way for estimating drilled pile capacity in Texas rock formations. Full details are included in the paper “Developed Predictive Design Equations for Drilled Shaft Capacities for Various Rock Formations by Conducting Site Investigation and Load Test”, by Hosam Salman, Ph.D, P.E., F. ASCE1, Anand J. Puppala, Ph.D., P.E., F. ASCE2, and Bhaskar C. S. Chittoori, Ph.D.3, in the upcoming IFCEE 2024 in Dallas.

To evaluate the 2024 approach, we put the method to the test by examining one axial load test on a 48-inch drilled pile, 95 ft in length. The lower half of the pile was installed in weather to progressively hard Eagle Ford shale. Through Osterberg cell load testing, the ultimate capacity was approximately 3150k at one inch of settlement. The following runs were performed using our DeepFND 2024 software:

a) FHWA GEC-10: Figure 4

b) TxDOT manual approach from TCP (Figure 5)

c) Salman 2021 TCP charts (Figure 6)

d) Salman et. al. 2024 equations with TCP limited to 2 inches min (Figure 7)

e) Salman et. al. 2024 equations with TCP not limited to 2 inches (Figure 8)

When we review the following the FHWA methods which were never meant for Texas rock formations underpredict the end bearing resistance significantly. On the other hand, the existing TxDOT methods significantly overpredict the available side shear resistance. The Salman 2021 and 2024 methods come much closer to the tested capacities. If the reasonable TCP limit of 2 inches is not used, then the tested capacity is much closer to the load test at 1” of displacement.

Figure 4: FHWA settlement prediction vs. load test

Figure 5: Predicted pile settlement for TxDOT manual approach vs. load test

Figure 6: Predicted pile settlement for Salman 2021 charts vs. load test

Figure 7: Predicted pile settlement for Salman 2024 methods without TCP limit vs. load test

Figure 8: Predicted pile settlement for Salman 2024 methods with TCP limit vs. load test

What you need to know

If you are here, you have likely read the whole article, in case you didn’t we recommend that you also use the proposed methods by Salman 2021 and 2024 vs. the standard TxDOT methods especially if you have drilled piles in Shale rocks.

Our Special Limited Time Offer

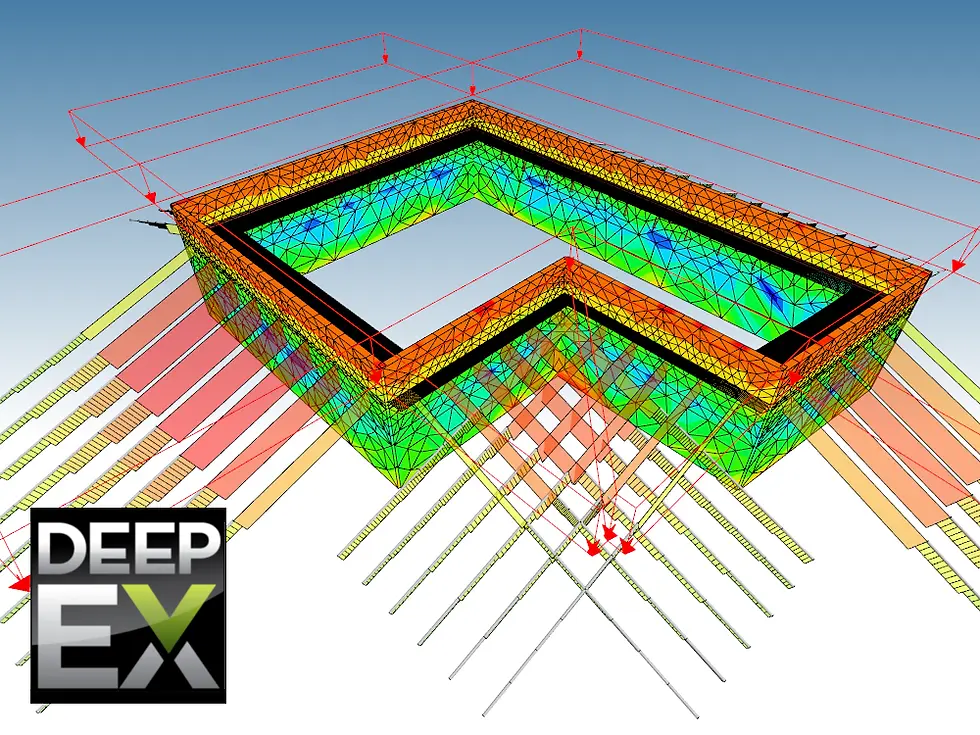

All these methods are incorporated in our DeepFND deep foundation software. In addition to TxDOT methods, DeepFND can also help you with the lateral pile analysis, pile groups, structural pile capacity, axial settlement methods, pile rafts, and 3D FEM capabilities.

Purchase by April 24th 2024, use promo code TXASCE10 on checkout, and receive a 10% discount.

References:

Salman, Hosam, PhD Thesis Dissertation-University of Texas Arlington 2021 - “UTILIZING LOAD TESTS AND SITE INVESTIGATION DATA TO PREDICT DESIGN LOAD CAPACITIES FOR DRILLED SHAFTS IN DIFFERENT GEOLOGIC FORMATIONS”

Salman, H., Puppala, A. J., & Chittoori, B. C. S. (2023). Utilizing Site Investigation and Load Tests to Predict Drilled Shaft Design Parameters and Capacities for Various Geological Formations. https://doi.org/10.1061/9780784484685.004

Texas Department of Transportation (TxDOT), 2020, “Geotechnical Manual”. Austin, Texas. http://onlinemanuals.txdot.gov/txdotmanuals/geo/geo.pdf

Book A free web presentation: