Helical Pile Design Verification - Pipe with Casing & Grout

- Dec 27, 2023

- 2 min read

Updated: Dec 28, 2023

3'' Pipe with External Casing and Grout with 8''-10''-12'' Helixes

A. Project description

This example presents a detailed example for calculating the ultimate axial capacity of a helical pile according to Vesic 1974 and Meyerhoff/Hansen method. Table 1 below presents assumed soil properties, Table 2 summarizes the soil stratigraphy, while Table 3 describes assumed helical pile properties.

Table 1: Soil properties

Table 2: Stratigraphy (Boreholes)

Table 3: Helical pile properties

We will examine three cases:

The pile as described in the previous table

The use of an external casing (Diameter: 8'' , length: 12 ft)

The use of an external casing as described above and 6'' grout extended to 8 ft from the pile bottom.

Soil Properties and Model in HelixPile

Pile Section Properties and Helix Configuration

B. Ultimate bearing capacity calculations – Cylinder failure method

B1. Manual calculations

For the cylinder latteral pressures factor, we will use the Mitch – Clemence method:

K = 0.09e(0.08fr) = 1.366

Table 4: Ultimate shear stress line force calculations.

Figure: Ultimate shear stress line force on cylinder body.

Cylinder strength: Fcylinder = A1 + A2 = 14120.725 + 9867.31 = 23988.035 lbs = 23.99 kips

Vesic method

Tip: Fult = 2.45 kips (compression)

Plate 1: Fult = 15.24 kips (compresion)

Plate 3: Fult = 32.95 kips (tension)

So, the utimate cylinder compression capacity is Fult, comp = 23.99 + 2.45 + 15.24= 41.68 kips

The utimate cylinder tension capacity is Fult, tension = 23.99 + 32.95 = 56.94 kips

Meyerhoff/Hansen

Tip: Fult = 3.32 kips

Plate 1: Fult = 20.62 kips

Plate 3: Fult = 44.59 kips

So, the utimate cylinder compression capacity is Fult, comp = 23.99 + 3.32 + 20.62 = 47.93 kips

The utimate cylinder tension capacity is Fult, tension = 23.99 + 44.59 = 68.58 kips

Ultimate shaft capacity calculations:

Case I (no grout, no external casing)

Table 5: Shaft resistance calculation parameters – Case I

Table 6: Shaft resistance calculations – Case I

Fshaft = A1+A2+A3+A4 = 7957.66 lbs = 7.96 kips

Figure: Shaft resistance diagram

Case II (external casing 8'' , no grout)

Table 7: Shaft resistance calculation parameters – Case II

Table 8: Shaft resistance calculations – Case II

Figure: Shaft resistance diagram

Fshaft = A1+A2+A3+A4+A5 = 10496.89 lbs = 10.5 kips

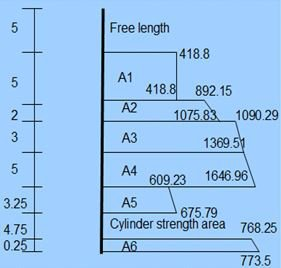

Case III (external casing 8'' , grout 6'')

Table 9: Shaft resistance calculation parameters – Case III

Table 10: Shaft resistance calculations – Case III

Figure: Shaft resistance diagram

Fshaft = A1+A2+A3+A4+A5+A6 = 17573.71 lbs = 17.57 kips

Table 11: Shaft and cylinder tension capacity – Vesic method

Table 12: Shaft and cylinder compression capacity – Vesic method

Table 13: Shaft and cylinder tension capacity – Meyerhoff/Hansen method

Table 14: Shaft and cylinder compression capacity – Meyerhoff/Hansen method

B2. Calculations with HelixPile

Figure: Compression and tension cylinder method results in HelixPile (Vesic method – Case I)

Figure: Compression and tension cylinder method results in HelixPile (Meyerhoff/Hansen method – Case I)

Figure: Compression and tension cylinder method results in HelixPile (Meyerhoff/Hansen method – Case II)

Figure: Compression and tension cylinder method results in HelixPile (Vesic method – Case III)

Figure: Compression and tension cylinder method results in HelixPile (Meyerhoff/Hansen method – Case III)

Table 15: Comparison between manual calculations and HelixPile results.